20+ Concrete Patio Designs to Elevate Your Backyard

Your concrete patio looks like a parking lot. That boring gray slab mocks you every time you glance outside, reminding you that your backyard lacks the warmth and character you see in design magazines. You’ve considered ripping it out and starting over with expensive pavers or natural stone, but the quotes make your wallet weep $8,000 to $15,000 for what you really want.

Here’s what contractors don’t tell you upfront: you’re sitting on the perfect foundation for a stunning outdoor space. That plain concrete patio you’re ready to demolish can transform into a custom showpiece for a fraction of replacement costs. Concrete Patio Designs range from $2 to $18 per square foot depending on technique, delivering stone-look elegance, vibrant colors, or artistic patterns without the premium price tag.

What Are the Most Popular Concrete Patio Ideas?

Concrete patio ideas have evolved dramatically over the past decade, transforming from basic gray slabs into sophisticated design elements that rival premium materials. The five techniques dominating today’s market each deliver distinct aesthetics and price points.

Concrete Patio Designs lead in popularity because they authentically replicate stone, brick, slate, or wood at 40-60% less cost than genuine materials. Contractors press texture mats into wet concrete while adding integral color or surface stains, creating realistic patterns with natural variation. Stained concrete patio finishes using acid or water-based stains produce translucent, variegated colors that improve with age, think weathered stone or aged leather in earth tones.

Exposed aggregate reveals decorative stones embedded throughout the concrete by washing away surface cement, delivering natural texture and slip resistance perfect for pool decks. Concrete scoring and engraving uses saws to cut patterns that mimic tile layouts, geometric designs, or custom borders on existing slabs. For pure color transformation, specialty concrete paint and epoxy coatings provide solid hues with optional decorative flakes, though they require reapplication every 3-5 years.

The beauty of concrete lies in its versatility; you can combine techniques for unique results, like stamping the center area while scoring decorative borders and staining everything in complementary tones. According to Concrete Network industry data, homeowners investing in decorative concrete ideas recover 60-75% of costs at resale while enjoying immediate aesthetic improvements that would cost 2-3 times more using alternative materials.

How Much Do Different Concrete Patio Designs Cost?

Understanding concrete patio cost breakdowns helps you budget realistically and choose treatments that maximize visual impact within your price range. Professional installation versus DIY approaches create significant price variations.

Concrete Patio Cost Comparison Table

| Concrete Finish | DIY Cost per Sq Ft | Professional Cost per Sq Ft | Lifespan | Best For |

| Basic Gray Concrete | $3-$6 | $6-$10 | 25-30 years | New construction, budget builds |

| Concrete Staining | $0.50-$2 | $3-$8 | 10-15 years | Existing slabs, color updates |

| Stamped Concrete | N/A (professional only) | $8-$18 | 15-25 years | Stone/brick replication |

| Exposed Aggregate | $4-$8 | $10-$16 | 20-30 years | Texture, slip resistance |

| Concrete Overlay | $3-$7 | $7-$15 | 10-20 years | Resurfacing damaged slabs |

| Painted Concrete | $1-$3 | $2-$5 | 3-5 years | Temporary color, rentals |

| Polished Concrete | N/A (professional only) | $8-$20 | 20+ years | Modern, industrial looks |

DIY concrete patio staining represents the most budget-friendly transformation purchase acid stain or water-based products from home centers for $40-$100 per gallon covering 200-400 square feet, add cleaning supplies and sealer, and complete the project over a weekend for $200-$600 total on a standard 200-square-foot patio. Professional stamped concrete patio installation costs $8-$18 per square foot installed, meaning a 300-square-foot patio runs $2,400-$5,400 compared to $4,500-$9,000 for natural stone pavers achieving similar looks.

Concrete resurfacing using overlay products repairs damaged slabs while adding texture and color for $7-$15 per square foot professionally or $3-$7 DIY. Hidden costs include surface preparation ($2-$5 per square foot for cleaning and repairs), concrete sealer application ($0.50-$2 per square foot), and potential grinding to remove old coatings ($3-$8 per square foot). The money-saving strategy that works consistently handles preparation and sealing yourself while hiring professionals for specialized techniques like stamping that require expertise and equipment.

What Is Stamped Concrete and How Does It Compare to Real Stone?

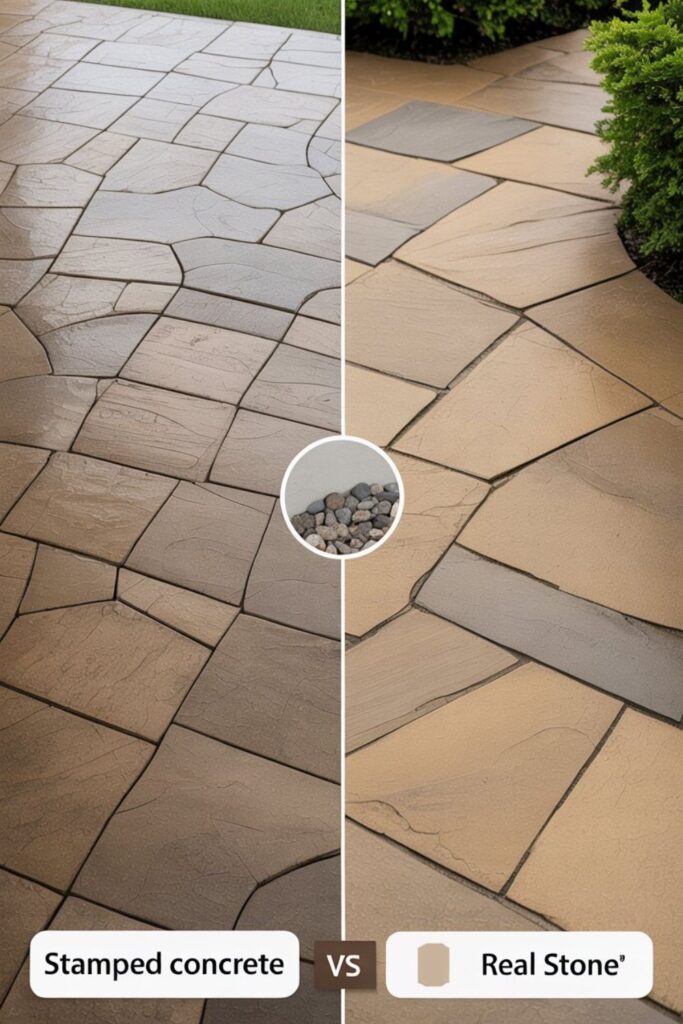

Stamped concrete patio designs replicate the appearance of natural stone, brick, slate, wood, and even cobblestone using specialized stamps pressed into freshly poured concrete. Understanding the process helps you evaluate whether this popular option suits your project.

Contractors pour colored concrete patios using integral color mixed throughout the concrete or color hardener broadcast on the surface. Before the concrete fully hardens, they press large texture mats or stamps into the surface, creating three-dimensional patterns that mimic various materials. Release agents prevent stamps from sticking while adding secondary color variations for realistic depth. The result textured concrete patio surfaces that look remarkably like premium materials from three feet away. Modern stamping techniques have improved dramatically: texture patterns now include natural edge variations, multiple stone sizes, and irregular layouts that avoid the repetitive “obviously fake” appearance of older installations.

Color options extend far beyond basic gray choose from 50+ standard hues or custom mix to match your home’s exterior palette. Stamped concrete costs $8-$18 per square foot installed versus $15-$35 for genuine natural stone or brick pavers, delivering 40-60% savings while maintaining similar visual impact. The durability equation favors concrete properly installed and sealed stamped surfaces lasting 15-25 years with minimal maintenance compared to natural stone requiring regular resealing, joint sand replacement, and individual unit repairs. However, when damage occurs, stamped concrete shows more dramatically: cracks appear as dark lines disrupting patterns, and repair patches rarely match original colors perfectly.

Natural stone allows simple replacement of individual damaged units. Climate considerations matter: stamped concrete performs beautifully in temperate and warm regions but faces challenges in extreme freeze-thaw cycles where improper installation leads to surface flaking. For maximum authenticity, combine stamping with concrete scoring along pattern lines and use multiple color applications to create depth and variation.

How Do You Stain Concrete Patios for Custom Colors?

Stained concrete patio finishes deliver rich, translucent colors with organic variation impossible to achieve with paint. Two primary staining methods acid-based and water-based produce distinctly different results suited to various design goals.

Acid stains create chemical reactions with minerals in concrete, producing earthy tones like terra cotta, browns, tans, and blue-greens with natural mottling and variation. The unpredictable nature of acid staining creates one-of-a-kind results no two areas look identical delivering organic beauty that mimics aged stone or weathered leather. Acid stains penetrate deep into concrete rather than sitting on top, making them incredibly durable and fade-resistant. However, color options limit to earth tones, and the application process requires careful safety precautions including protective gear and proper ventilation. Water-based stains offer broader color palettes including vibrant reds, blues, greens, and purples along with traditional earth tones.

They provide more predictable, uniform coverage than acid stains, making them ideal when you need consistent color. Water-based products work well for logos, patterns, or artistic designs requiring precise color placement. For DIY concrete patio staining, water-based stains prove more forgiving: they clean up with soap and water, don’t produce toxic fumes, and allow easier color correction during application. The staining process follows consistent steps: clean concrete thoroughly using degreaser and pressure washing, repair cracks and damage, test stain on inconspicuous areas to verify color, apply stain in thin coats using pump sprayers or brushes, allow proper drying time (4-24 hours depending on product), neutralize acid stains if used, and seal with quality concrete sealer for protection.

What Are the Best DIY Concrete Patio Ideas for Beginners?

Beginner-friendly DIY concrete patio projects deliver impressive results without requiring professional expertise or expensive equipment. Success comes from choosing appropriate techniques and following proper preparation protocols.

Concrete Patio Designs ranks as the easiest transformation for existing slabs: purchase water-based stain products, clean concrete thoroughly, apply thin coats following label directions, and seal for protection. Expect to spend $200-$500 on materials for 200 square feet and complete the project over two days. Painted concrete using specialty patio paint provides solid color coverage for $150-$400 total, though results last only 3-5 years before requiring reapplication. For texture without stamping complexity, broom finishes create subtle slip-resistant patterns by dragging stiff brooms across fresh concrete in consistent directions; this works beautifully on new pours or thick overlay applications.

Concrete scoring transforms existing slabs by cutting pattern lines using circular saws equipped with diamond blades, rent equipment for $75/day and create tile patterns, borders, or geometric designs over a weekend. This technique pairs beautifully with staining: score the pattern first, then stain different sections in contrasting colors for faux tile appearances. Decorative concrete overlays provide thin (1/4-inch) resurfacing that covers damaged concrete while accepting stamps, stains, or scoring. Purchase bagged overlay products at home centers, mix following instructions, trowel onto prepared surfaces, and add desired finishes before setting.

One genuinely beginner-friendly artistic technique, concrete stenciling, combines with staining or painting to create medallions, borders, or repeating patterns. Tape purchased stencils onto clean concrete, apply contrasting stain or paint colors, remove stencils, and seal results. The DIY mistake that ruins projects rushing surface preparation. Concrete must be completely clean, dry, and free of previous sealers or coatings for new treatments to bond properly. Invest time in thorough pressure washing, chemical cleaning if needed, and proper drying periods before applying decorative finishes.

How Can You Make Old Concrete Patios Look New Again?

Concrete resurfacing breathes new life into damaged, stained, or outdated slabs without complete replacement. Multiple approaches address different condition levels from cosmetic updates to structural repairs.

For concrete with minor surface wear but solid structural integrity, cleaning and sealing provides immediate improvement at minimal cost. Pressure wash at 3000+ PSI to remove dirt, algae, and loose material, apply concrete cleaner or degreaser for stubborn stains, allow complete drying for 48 hours, then apply penetrating concrete sealer for protection and enhanced appearance. This $100-$300 refresh makes 10-15 year old concrete slab patio surfaces look significantly better. When surface damage includes minor cracks, spalling, or pitting, thin overlay products resurface the entire slab with 1/4 to 1/2 inch of new material. These polymer-modified concrete mixes bond to existing surfaces and accept any decorative finish including stamping, staining, or scoring.

Professional overlay installation costs $7-$15 per square foot while DIY approaches run $3-$7 using bagged products from home centers. For textured concrete patio surfaces with failed finishes, grinding removes old sealers, paints, or damaged surface layers, creating fresh concrete that accepts new treatments. Rent concrete grinders for $100-$200 per day and work systematically across the slab, then apply desired decorative finishes. One effective cosmetic solution: concrete paint or solid-color stains cover a multitude of sins including discoloration, minor damage, and failed previous coatings. Modern concrete paints formulated specifically for Concrete Patio Designs include bonding primers that adhere to challenging surfaces and flexible topcoats that move with concrete as it expands and contracts.

Color options extend across the spectrum, allowing complete aesthetic transformation. The professional approach to comprehensive renewal combines techniques strategically. Repair significant cracks with flexible concrete caulk, overlay heavily damaged sections, apply acid or water-based stains for color and variation, add scored patterns for visual interest, and seal everything with high-quality sealer for protection and sheen. This layered approach costs $5-$12 per square foot DIY but creates custom results rivaling new installations.

What Concrete Patio Designs Work Best in Different Climates?

Climate significantly impacts concrete patio designs durability and maintenance requirements. Smart material choices and finishing techniques prevent common weather-related failures.

Freeze-thaw regions require special attention; concrete must cure properly with adequate air entrainment (4-7% air content) that allows water to expand when frozen without cracking. Avoid stamped concrete patio installations in areas experiencing more than 30 freeze-thaw cycles annually unless contractors use premium mix designs and proper installation protocols. Instead, consider exposed aggregate finishes that hide minor surface scaling, or simple broom finish textures that perform reliably in harsh climates. Always seal concrete in cold regions using penetrating sealers that don’t trap moisture topical sealers can blister and peel when moisture freezes beneath the surface.

Hot, arid climates face different challenges: intense UV exposure fades colored Concrete Patio Designs over time, while extreme heat causes surface expansion that cracks improperly installed slabs. Use integral colors mixed throughout concrete rather than surface-applied color hardeners that fade integral colors to maintain appearance even as surface wears. Light-colored concrete stays significantly cooler underfoot than dark gray or stamped patterns using dark release agents. Consider polished concrete finishes in desert regions for their heat-reflective properties and extreme durability. Humid, rainy climates demand excellent drainage slope concrete away from structures at minimum 1/4 inch per foot and avoid low spots where water pools.

Textured concrete patio surfaces like exposed aggregate or light broom finishes provide better slip resistance when wet compared to smooth troweled or polished surfaces. Tropical and coastal regions face salt air and constant moisture that accelerate concrete deterioration. Apply penetrating silane/siloxane sealers that repel water and chlorides while allowing concrete to breathe, reapplying every 2-3 years. The climate-adaptable solution that works everywhere quality concrete properly installed with appropriate mix design, adequate curing time, proper sealing, and climate-specific finishing techniques. Don’t let budget contractors skip critical steps like proper base preparation, vapor barriers in damp areas, control joint placement, or adequate curing periods.

How Do You Choose Colors for Decorative Concrete Patios?

Colored concrete patios require thoughtful color selection that complements your home’s exterior while creating the outdoor ambiance you desire. Poor color choices create jarring contrasts that diminish curb appeal.

Start with your home’s existing color palette, identify brick, siding, trim, and roof colors, then choose concrete tones that harmonize rather than compete. The classic approach pulls one dominant color from your home and uses it as your concrete base tone, then adds accent colors in 2-3 shade variations for depth. Earth tones tans, browns, terra cottas, and warm grays work universally well because they mimic natural materials and complement virtually any architectural style.

Stained concrete patio finishes in these colors age beautifully, developing richer patinas over time. For modern or contemporary homes, cool grays, charcoal, and blue-gray tones create sophisticated minimalist aesthetics that pair with metal, glass, and clean-lined architecture. Consider light reflectivity: dark colors absorb heat and show dirt, dust, and water spots prominently, while light colors reflect heat, stay cooler underfoot, and camouflage minor staining. In hot climates, light beiges, tans, and cool grays prevent surface temperatures from becoming uncomfortably hot. The 60-30-10 color rule applies to decorative concrete ideas: use one dominant color for 60% of the space (primary concrete color), a secondary complementary color for 30% (border, accent areas), and an accent color for 10% (small details, scored patterns).

Test colors before committing: request sample boards from concrete contractors or purchase small quantities of stain to test on inconspicuous areas. Colors appear different when wet versus dry, in sunlight versus shade, and change subtly as concrete ages and sealers wear. For stamped concrete replicating stone, research actual stone colors in your region: Arizona flagstone runs terra cotta and buff, while Pennsylvania bluestone shows gray and blue tones. Matching regional stone creates authentic appearances. The professional color technique that adds realism layer multiple colors for depth. Apply a lighter base tone, then add darker grout lines, edges, and random accent areas where natural weathering would occur, finishing with antiquing stains that settle in texture crevices.

What Are the Best Concrete Patio Patterns and Textures?

Pattern and texture selection dramatically impacts concrete patio ideas visual appeal and functionality. Different techniques suit various design styles from traditional to contemporary.

Stamped concrete offers dozens of pattern options replicating specific materials. Popular choices include random stone (irregular flagstone pieces), ashlar slate (rectangular stones in stacked patterns), cobblestone (rounded stones for old-world charm), wood plank (horizontal boards for deck appearances), and European fan (curved patterns radiating from corners). Pattern scale matters: large stone patterns suit spacious patios while smaller brick or tile patterns work better in compact spaces.

For concrete scoring techniques, grid patterns mimicking tile layouts prove most popular square tiles in 12×12, 16×16, or 18×18-inch layouts create classic appearances. Diagonal grids add visual interest and make spaces appear larger. Geometric patterns using hexagons, diamonds, or custom shapes deliver contemporary sophistication. Border designs frame patios beautifully: score 12-18 inch borders around perimeters in contrasting colors or patterns, creating defined edges that separate patio spaces from surrounding landscape. Exposed aggregate finishes vary by aggregate type; smooth river pebbles create organic natural looks, crushed granite delivers sparkle and color variation, while decorative glass aggregates add contemporary flair.

Aggregate size impacts texture: 1/4-inch stones create subtle texture, 3/8-inch provides moderate texture and slip resistance, while 1/2-inch or larger creates bold textural statements. Simple broom finish patterns offer understated elegance; straight parallel lines appear formal, slight curves add softness, and swirled circular patterns create artistic interest. For texture without pattern, salt-finished concrete involves broadcasting rock salt onto fresh concrete then washing it away after setting, leaving small divots for organic texture. The designer secret for professional results combines multiple textures and patterns strategically. Use stamped stone in main sitting areas, add scored borders in complementary patterns, incorporate exposed aggregate bands as visual transitions, and ensure all elements share cohesive color palettes.

Read More About: Small Space Organization: Expert Tips And Smart Storage Solutions

How Long Does Concrete Patio Sealing Last and Why Is It Important?

Concrete sealer application represents the single most important maintenance task for preserving decorative concrete’s appearance and structural integrity. Understanding sealer types and schedules prevents premature failure.

Penetrating sealers soak into concrete pores, chemically reacting to create water-repellent barriers while allowing concrete to breathe. These products protect without altering appearance significantly, and concrete maintains its natural matte finish or slight sheen. Penetrating sealers last 3-5 years before requiring reapplication and work beautifully in freeze-thaw climates where topical sealers fail. Topical sealers form protective films on concrete surfaces, enhancing colors dramatically and adding glossy, satin, or matte sheens based on product formulation.

Acrylic sealers cost $25-$50 per gallon, cover 250-400 square feet, and last 1-3 years depending on traffic and weather. Polyurethane and epoxy sealers provide superior protection lasting 5-10 years but cost $75-$200 per gallon and require professional application. For stained concrete patio finishes, sealers intensify colors by 30-50%, transforming subtle earth tones into rich saturated hues. They prevent staining from spills, protect against UV fading, reduce water absorption that causes freeze damage, and make surfaces easier to clean. Unsealed colored concrete patios fade within 2-3 years, absorb stains permanently, and deteriorate significantly faster than sealed surfaces. Application timing matters: seal new concrete 28 days after pouring to allow complete curing, reapply topical sealers annually in high-traffic areas or every 2-3 years in protected spaces, and refresh penetrating sealers every 3-5 years.

The sealing mistake that causes problems applying sealers to dirty, damp, or improperly prepared surfaces. Clean concrete thoroughly, remove previous failed sealers if necessary, allow complete drying for 24-48 hours, and apply sealers in thin coats during mild weather (50-90°F). Test sealers on small inconspicuous areas first to verify sheen and color enhancement match expectations. For DIY concrete patio maintenance, budget $100-$300 every 2-3 years for quality sealer and application supplies. This small investment extends your concrete’s life by decades while maintaining a beautiful appearance.

What Are Common Mistakes to Avoid With Concrete Patio Projects?

Concrete patio ideas gone wrong cost thousands in repairs and replacements. Learning from common errors saves money and frustration while ensuring successful outcomes.

The most expensive mistake is inadequate base preparation. Concrete requires 4-6 inches of compacted gravel base for stability and drainage, yet contractors sometimes pour directly on poorly prepared soil to save time and money. This leads to settling, cracking, and premature failure within 3-5 years. Always verify proper excavation depth, quality base material, and mechanical compaction before concrete placement. Rushing concrete curing ruins decorative finishes: contractors sometimes start stamping, scoring, or applying release agents too early when concrete remains too soft, or wait too long when it’s too hard. Proper timing requires experience and attention stamping works best when concrete supports knee boards without impression but accepts pattern depth from stamps.

Similarly, applying concrete sealer too soon traps moisture causing whitish haziness, while waiting too long allows stains and damage. Poor drainage planning creates persistent problems: water pooling on concrete slab patio surfaces leads to freeze damage, staining, and algae growth. Ensure minimum 1/4-inch per foot slope away from structures and avoid low spots in the surface. For stamped concrete patio installations, repetitive pattern placement screams artificial stones should vary in size, shape, and placement. Quality installations use multiple stamp tools with random rotation and varied pattern arrangements. Color mistakes include choosing too-dark shades that absorb excessive heat, using colors that clash with home exteriors, or applying insufficient color that fades within months.

One structural error that plagues DIY projects omitting or improperly spacing control joints. Concrete naturally cracks as it cures and experiences temperature changes. Control joints direct those cracks to predetermined locations, keeping them straight and less noticeable. Space control joints 2-3 times the concrete thickness in feet (4-inch thick concrete gets joints every 8-12 feet). The maintenance mistake that accelerates deterioration neglecting regular sealing and cleaning. Even premium concrete needs sealer reapplication every 1-5 years depending on product type, and annual cleaning prevents stain accumulation and surface degradation.

How Do Concrete Overlays Compare to Complete Patio Replacement?

Concrete resurfacing using overlay products offers cost-effective alternatives to demolition and replacement when existing slabs maintain structural soundness. Understanding when overlays work versus when replacement becomes necessary saves money and delivers better outcomes.

Concrete overlays bond to existing surfaces, creating new 1/4 to 3-inch thick layers that hide damage while accepting any decorative finish. Modern polymer-modified overlays flex slightly with existing concrete movement, reducing crack transmission from old to new surfaces. They cost $3-$15 per square foot depending on thickness and finishes compared to $6-$18 for complete replacement including demolition and disposal. Time differences favor overlays too: resurface 300 square feet in 2-3 days versus 5-7 days for full replacement including demolition, base work, and new installation. Overlays work beautifully when existing concrete shows cosmetic damage (surface spalling, staining, minor cracks) but maintains solid structure the slab doesn’t rock when walked upon, major cracks don’t widen significantly, and drainage remains adequate.

They fail when underlying concrete suffers structural problems: widespread deep cracking, significant settling or heaving, chronic drainage issues pooling water, or erosion undermining the slab. Attempting to overlay fundamentally flawed concrete wastes money and new surfaces develop matching problems within months. One scenario favoring overlays decorative concrete ideas updates for style changes. That 1990s pink-stained patio looks dated, but the concrete remains solid. Overlay, stamp, and stain in contemporary colors for a fraction of replacement costs. Similarly, overlays rescue ugly utilitarian concrete slab patio surfaces in new construction, adding custom finishes builders excluded from base contracts. The technical limitation of overlays’ minimal thickness means limited stamping depth.

Deeply textured stone patterns look shallow on thin overlays compared to full-thickness stamped concrete. Consider spray-down or hand-carved overlays that create texture through surface techniques rather than stamping depth. For DIY projects, overlays prove more forgiving than pouring new concrete: smaller batch sizes, simpler mixing, and thinner applications reduce the technical complexity and physical demands compared to placing several yards of concrete.

What Concrete Finishes Work Best for Different Architectural Styles?

Matching concrete patio designs to your home’s architecture creates cohesive outdoor spaces that enhance rather than clash with existing aesthetics. Different styles demand distinct concrete treatments.

Modern and contemporary homes pair beautifully with sleek polished concrete finishes in cool grays, charcoal, or pure white. Keep patterns geometric and minimalist large format scored squares, linear scoring creating plank effects, or plain smooth troweled surfaces. Avoid busy patterns or excessive color variation. For texture, choose subtle broom finish in straight parallel lines or opt for lightly exposed aggregate using small uniform stones. Traditional and colonial architecture demands classic materials: stamped concrete replicating brick in herringbone or running bond patterns works perfectly, as do ashlar slate or random stone stamps in traditional earth tones.

Add scored borders mimicking sailor’s valentine or compass rose medallions for period-appropriate details. Craftsman-style homes benefit from textured concrete patio surfaces emphasizing natural materials: exposed aggregate using regional stones, acid-stained finishes in earth tones showing organic mottling, or simple integral color concrete with scored geometric patterns inspired by arts and crafts tile work. Mediterranean and Spanish revival styles call for warm-toned colored concrete patios: terra cotta, golden tan, and warm brown stains paired with saltillo tile stamp patterns or random flagstone. Consider adding hand-carved accents or decorative scoring mimicking intricate tile patterns. Ranch and mid-century modern homes look best with horizontal design elements: long linear scored patterns, rectangular stamp patterns laid horizontally, or simple clean finishes in neutral grays and tans. Avoid fussy details or overly decorative elements.

Farmhouse and cottage styles allow more creative freedom: random stone stamped concrete in lighter earth tones, painted concrete in chalky whites or soft grays, or combinations of concrete scoring and staining creating faux tile appearances. The color matching principle that always succeeds is to pull three colors from your home’s exterior (brick, trim, stone accents) and repeat them in your concrete using those exact tones for base color, borders, and accent scoring. This creates seamless visual connections between home and outdoor spaces.

How Can You Add Decorative Details to Basic Concrete Patios?

Transforming plain concrete slab patio surfaces into custom showcases doesn’t require complete resurfacing. Strategic decorative additions elevate basic concrete aesthetically while staying budget-friendly.

Concrete scoring creates dramatic visual impact for $2-$5 per square foot. Rent concrete saws with diamond blades, mark pattern lines using chalk lines or tape, and cut 1/4 to 1/2-inch deep grooves following designs. Popular approaches include 12×12-inch or 16×16-inch grid patterns mimicking tile, diagonal grids appearing more dynamic, border frames separating patio zones, or artistic curves and geometric shapes. Combine scoring with staining: cut patterns first, then stain different sections in contrasting colors for faux tile appearances costing $4-$10 per square foot total. Stenciled designs add artistic flair without permanent commitment: purchase or create custom stencils, tape them securely to clean concrete, apply concrete paint or stain in contrasting colors, carefully remove stencils, and seal results.

Create border patterns, corner medallions, or repeating geometric motifs for $100-$400 including materials. For three-dimensional texture, hand-carving tools allow artistic customization of fresh concrete overlay applications: create stone-like joints, wood grain patterns, or custom designs limited only by imagination and skill. Embedded materials add unique character: press decorative stones, glass pieces, pottery shards, or metal elements into concrete surfaces before final setting, creating mosaic effects or personalized touches. Borders and bands transform basic spaces: pour colored concrete borders around existing gray slabs, add exposed aggregate bands as transitions between spaces, or frame patios with brick or stone edges contrasting with concrete centers.

Saw-cut expansion joints become design features when filled with colored caulk, decorative stones, or contrasting concrete: cut joints wider (1/2-inch), clean thoroughly, and fill with chosen materials creating visual interest from functional necessities. One simple yet effective detail round edge forms during new pours or grind edges smooth on existing slabs. Bullnose edges appear more finished and intentional than raw 90-degree corners, elevating perceived quality significantly for minimal effort.

What Tools and Materials Do You Need for DIY Concrete Projects?

Successful DIY concrete patio projects require specific tools and materials. Having proper equipment before starting prevents mid-project delays and ensures professional-quality results.

For concrete staining projects, essential supplies include concrete cleaner or degreaser ($15-$30 per gallon), stiff-bristle scrub brushes ($10-$20), pump sprayer for application ($25-$60), protective equipment including gloves, goggles, and respirator ($40-$80), acid or water-based stain ($40-$100 per gallon covering 200-400 square feet), neutralizing solution for acid stains ($15-$25), and quality concrete sealer ($25-$150 per gallon depending on type). Total material costs for 200-square-foot projects run $200-$600. Painting concrete requires similar supplies plus specific concrete paint or epoxy coating ($30-$80 per gallon), bonding primer ($25-$50), and potentially concrete etching solution ($20-$40).

How Do Weather Conditions Affect Concrete Patio Installation?

Weather dramatically impacts concrete work success, determining when to pour, apply finishes, and seal surfaces. Understanding environmental factors prevents costly failures and ensures durable concrete patio ideas outcomes.

Temperature controls concrete curing speed: ideal conditions fall between 50-85°F. Below 50°F, concrete cures too slowly, extending finishing time windows but risking freeze damage if temperatures drop below 32°F before initial set. Above 85°F, concrete sets rapidly, reducing working time for stamping or finishing while increasing cracking risk from rapid moisture evaporation. Hot weather demands special protocols pour early morning when temperatures remain coolest, use retarding admixtures slowing set time, keep fresh concrete shaded, and spray fine water mist over surfaces to prevent premature drying.

Cold weather requires accelerators speeding set time, insulated blankets protecting fresh concrete, and extended curing periods before applying decorative finishes. Humidity affects stained concrete patio applications significantly: acid stains require surface moisture for proper reaction, so humid conditions work beautifully while arid climates need pre-dampening. Water-based stains prefer drier conditions for even penetration. Wind accelerates concrete drying during installation, creating surface crazing and reduced strength. Erect wind breaks when gusts exceed 10 mph during pours. Rain poses obvious problems: never pour concrete when precipitation threatens within 24 hours.

Fresh concrete washed by rain develops rough pitted surfaces and weakened strength. If unexpected rain occurs during finishing, cover concrete immediately with plastic sheeting secured at edges. For concrete sealer application, mild dry weather proves essential: temperatures between 50-80°F, low humidity, and zero rain forecast for 24 hours after application. Applying sealer in high humidity causes whitish haziness, while excessive heat creates bubbles and uneven coverage. The seasonal timing that works best schedules concrete projects for spring or fall in most climates when moderate temperatures and lower humidity create ideal working conditions. Avoid mid-summer heat and winter cold unless working with experienced contractors using proper climate-control methods.

What Maintenance Does Decorative Concrete Require?

Decorative concrete ideas deliver stunning aesthetics that last decades when properly maintained. Simple regular care preserves beauty while preventing expensive repairs.

Daily maintenance involves sweeping or blowing debris that causes staining and abrasive wear. Weekly washing with mild detergent and water removes spills and buildup before they penetrate surfaces, use soft-bristle brushes on textured concrete patio surfaces and avoid harsh chemicals or pressure washing above 1500 PSI that damages sealers. Address spills immediately: oil, grease, and acidic substances etch concrete and stain permanently if left for days. Blot rather than wipe to avoid spreading, then clean with appropriate solutions (degreaser for oil, baking soda paste for acids).

Seasonal tasks include thorough deep cleaning before resealing: pressure wash at 1500-2500 PSI using concrete-safe cleaners, allow complete drying, and reapply concrete sealer following manufacturer schedules (annually for high-traffic topical sealers, every 2-3 years for standard applications, every 3-5 years for penetrating sealers). Spring inspections identify damage from winter freeze-thaw cycles: repair cracks using flexible concrete caulk, patch spalled areas with concrete overlay products, and address any settling or drainage changes. Fall preparation includes removing leaves and organic material that stain surfaces, ensuring proper drainage away from structures, and considering additional sealer coats before winter in harsh climates.

For stamped concrete patio maintenance, protect patterns by avoiding abrasive cleaning methods, using furniture pads under chairs and tables, and reapplying sealer that enhances colors and protects texture details. Colored concrete patios need UV-protective sealers reapplied more frequently in sunny exposures to prevent fading every 1-2 years for optimal color retention. The maintenance mistake that accelerates deterioration using de-icing salts in winter. Salt damages concrete surfaces, especially decorative finishes, causing scaling and discoloration. Use sand or kitty litter for traction instead. One pro maintenance tip that extends concrete life significantly doesn’t let vegetation grow in control joints or along edges. Roots create pressure that cracks concrete, while organic material retains moisture accelerating deterioration. Keep joints clean and sealed.

Read More About: Stunning Backyard Patio Ideas for a Beautiful Transformation

How Do You Repair Damaged Concrete Patios?

Even well-maintained concrete slab patio surfaces eventually develop damage requiring repair. Matching existing finishes presents challenges but proves manageable with proper techniques.

Hairline cracks under 1/8-inch wide need flexible polyurethane or silicone concrete caulk, clean cracks thoroughly, apply caulk, smooth with wet finger, and allow full curing. For stained concrete patio surfaces, caulks come in multiple colors for reasonable matching, though perfect matches prove elusive.

Wider cracks require vinyl concrete patching compounds: grind crack edges to create inverted V-shape for better bonding, clean thoroughly, apply patching compound following product directions, and feather edges to blend. Matching stain color to existing finishes requires test applications on inconspicuous areas first. Spalled or chipped areas demand more extensive repairs: remove loose material with chisel or grinder, create edges perpendicular to surface, apply bonding agent, fill with patching compound or thin concrete overlay, and finish to match surrounding texture. For stamped concrete repairs, replicating patterns proves nearly impossible, so consider cutting damaged sections to control joints or scored pattern lines, then overlay and re-stamp entire sections. Color matching challenges all concrete repairs: new patches appear lighter than aged concrete initially.

Mix integral color or add stains to patching materials attempting matches, understanding results improve as repairs age and weather. One clever repair technique embraces imperfection. On textured concrete patio surfaces, add intentional distressing around repairs using acid stains or antiquing agents that camouflage patches while creating aged patina on surrounding areas. For settlement issues where sections sink, mudjacking or foam injection raises concrete to proper levels before surface repairs.

Frequently Asked Questions

What is the cheapest way to redo a concrete patio?

The most affordable concrete patio ideas approach involves DIY staining using water-based products costing $200-$500 for 200 square feet. Clean concrete thoroughly with pressure washer and degreaser, apply stain in thin coats using pump sprayer, and seal with acrylic sealer. Alternatively, paint concrete using specialty patio paint for $150-$400, though results last only 3-5 years before requiring reapplication. Both options deliver dramatic visual transformation over single weekends without professional labor costs.

How long does stamped concrete last?

Stamped concrete patio installations last 15-25 years with proper maintenance including regular sealing every 2-3 years and prompt crack repairs. Quality matters significantly: proper base preparation, adequate concrete thickness (minimum 4 inches), and quality materials extend lifespan to upper ranges. Harsh freeze-thaw climates reduce longevity compared to temperate regions. Eventually, surface patterns wear from traffic and weather, requiring concrete resurfacing or replacement.

Can you stain old concrete patios?

Yes, stained concrete patio treatments work beautifully on existing concrete regardless of age, provided surfaces are structurally sound and properly prepared. Clean thoroughly removing all dirt, grease, sealers, and coatings using pressure washing and chemical strippers if needed. Allow complete drying for 24-48 hours before applying acid or water-based stains. Old concrete often shows more color variation than new concrete, creating attractive organic mottling. Test stains on inconspicuous areas first to verify color results.

Is stamped concrete more expensive than pavers?

Stamped concrete costs $8-$18 per square foot installed versus $12-$25 for concrete pavers and $15-$35 for natural stone pavers, making stamped concrete 30-50% less expensive than comparable materials. However, paver repairs prove simpler to replace individual damaged units versus patching visible repairs on stamped surfaces. Consider long-term maintenance costs and regional pricing variations when comparing options for your specific project.

How do you make concrete patios not slippery?

Add texture using broom finish during installation, specify exposed aggregate surfaces, or apply slip-resistant sealer additives. For existing concrete slab patio surfaces, use concrete resurfacing products with non-slip aggregates, apply textured overlay coatings, or add slip-resistant treatments painted or sprayed onto surfaces. Maintaining regular cleaning algae, moss, and organic buildup creates hazardous slippery conditions even on textured surfaces. Consider strategic placement of outdoor rugs in high-traffic areas for additional traction.

Can you pour concrete over the existing patio?

Yes, concrete overlay products bond to existing slabs creating new surfaces 1/4 to 3 inches thick accepting any decorative finish. Existing concrete must be structurally sound without major cracks, severe settling, or chronic drainage problems. Clean thoroughly, profile surface using grinding or etching for proper bonding, apply bonding agents, and install overlay following product specifications. This approach costs $3-$15 per square foot versus $6-$18 for complete removal and replacement.

CONCLUSION

Concrete patio ideas span simple weekend staining projects costing a few hundred dollars to elaborate stamped installations rivaling premium materials at fraction of costs. Your existing concrete foundation holds enormous potential for transformation that boring gray slab can become the outdoor showcase you’ve envisioned through strategic decorative treatments. Match techniques to your budget, skill level, and design preferences. DIY concrete patio staining delivers impressive results for minimal investment and basic skills.

Professional stamped concrete patio installations create authentic stone appearances lasting decades. Combine approaches strategically: stain existing areas, add scored patterns for visual interest, and seal everything for protection and enhancement.

Success requires proper preparation more than expensive materials. Clean surfaces thoroughly, repair damage before applying decorative treatments, choose colors complementing your home’s architecture, and maintain regular sealing schedules that protect your investment. Whether you spend $200 on staining supplies or $5,000 on professional stamped installation, quality decorative concrete ideas transform outdoor living spaces while adding property value.